LX-300 sheet machine edge material online crusher one drag one

Key words: crimping machine, packaging machine

cup counting machine

Category:

Description

The LX-300 model series sheet and edge material recycling machine is suitable for producing qualified products and more than two edge materials when the production line equipment of the sheet material machine is working. The edge materials are kept clean and dry while being produced, and enter the crushing chamber immediately and synchronously after being compacted by the tractor, and are cut into sheet-like granules, and then the crushed materials are immediately blown to the material inlet of the extruder through the fan, the small screw feeder and the main screw together will press the new and old materials into molding and recycling, so as to achieve 100% recycling of the edge materials. In this process, the edge materials will not be polluted by oxidation and humidification (blowing in steam), and will not cause physical strength stress of the extruded products and damage to the color luster. Therefore, the quality of the products can be improved. The benefits of automatic recycling of the edge materials include cost and material saving, the greatest effect of improved production process management, increased competitiveness and improved environment is to improve traditional productivity.

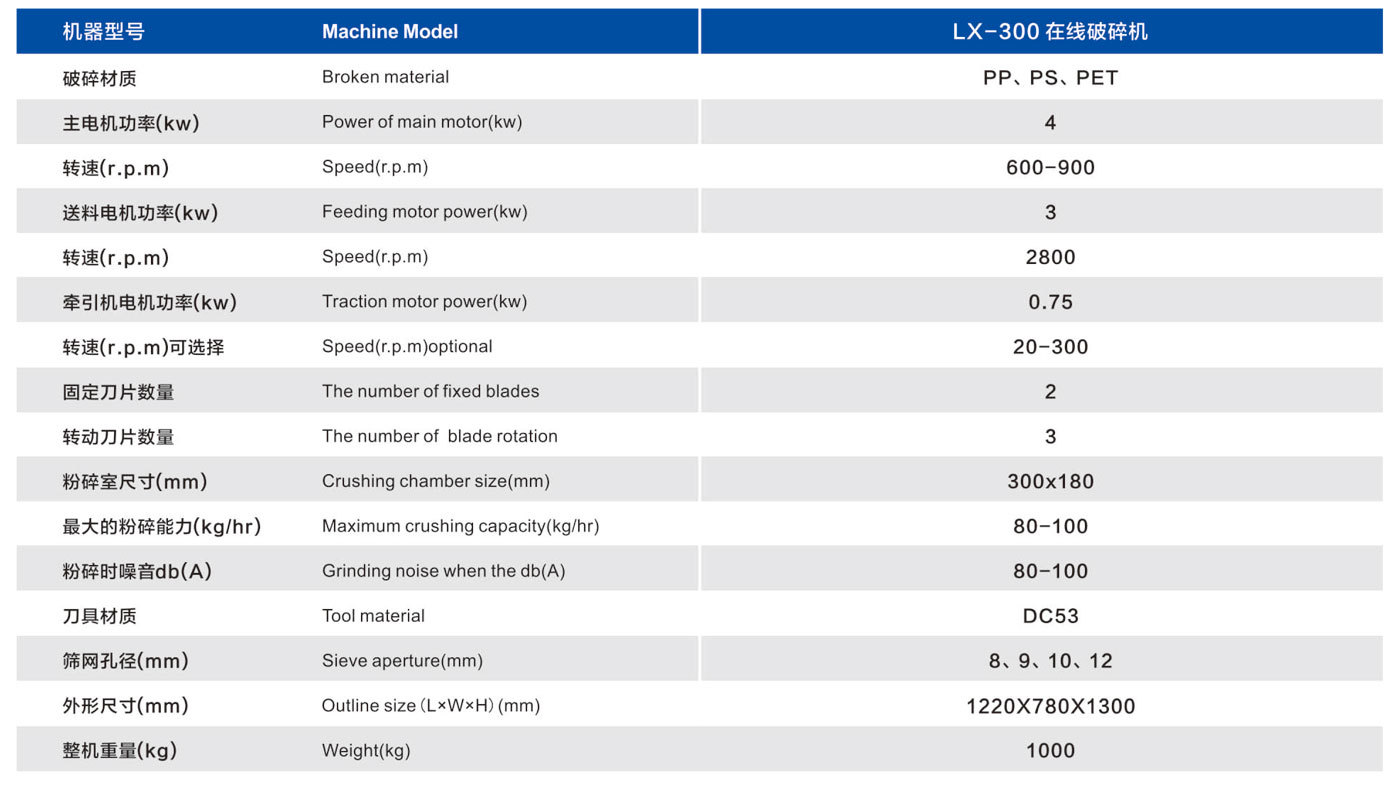

Main technical parameters

(Click on the image to enlarge)

Due to the difference in material form and material, the maximum crushing capacity is only for reference.

Related Products

Product Query