PRODUCTS

Boutique Recommended

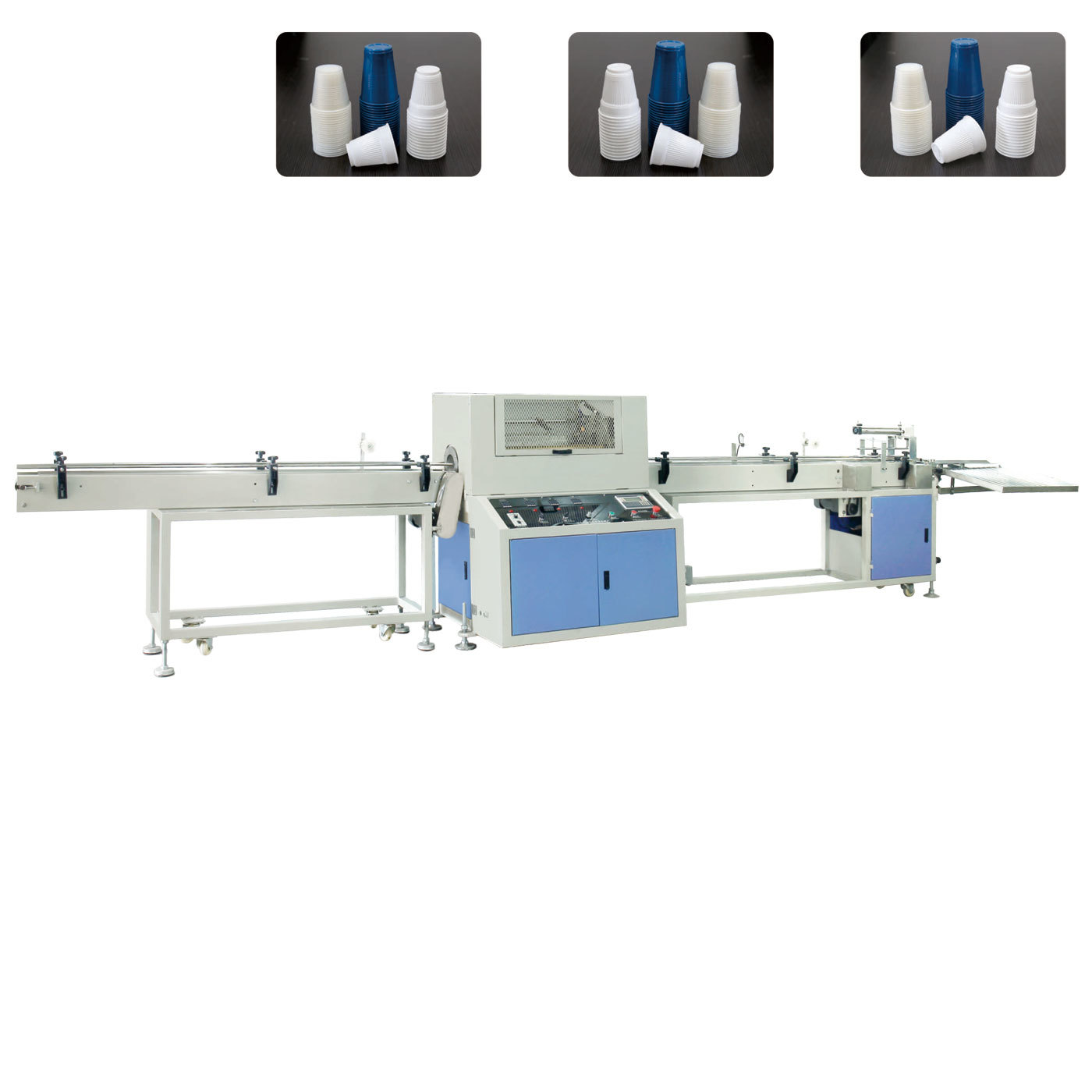

Our company specializes in the production of counting packaging machines, crimping machines, in-line crushing machines, food packaging machines, etc.

Honesty-Credibility First

Guangdong Shantou Weicheng Machinery Co., Ltd. is located in the famous coastal city, Shantou City, a special economic zone of China. The company is an enterprise integrating scientific research, design, manufacturing, sales and service, with integrity as its purpose and relying on science and technology. The company specializes in the production of counting packaging machines, crimping machines, online crushers, food packaging machines and other products. The products are well received by users. In line with the business philosophy of "reputation first, quality first", Weicheng Machinery will continue to be sincere

Service, common development with the majority of users to create good results.

Welcome to visit Weicheng company guidance.

Company started

Company covers an area

Company's existing employees

Sales Region

Hot information

Honesty-Credibility First

Weicheng Machinery

How to reduce the air generated during the packaging process

Weicheng Machinery

Weicheng Machinery

Strong strength

⊙ There are 50 employees and more than 10 professional technicians. Have advanced manufacturing equipment

Quality Assurance

Products are well received by the majority of users in line with the "reputation first, quality first" business philosophy

Service Support

The company's integrity, strength and quality of products recognized by the industry.